PTFE - Technical section

Virgin PTFE

granular from suspension polymerization homopolymer and modified

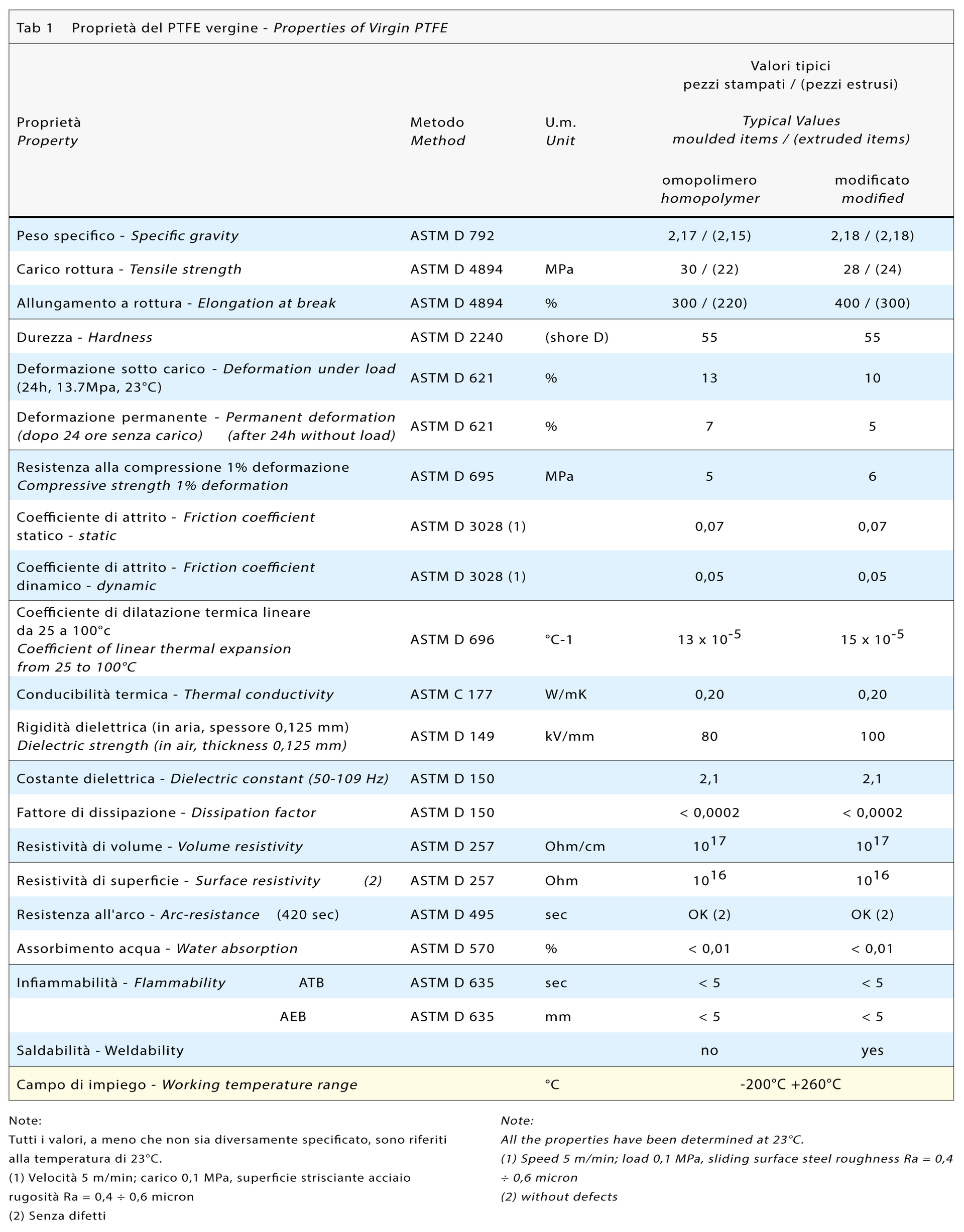

Table 1 shows the typical properties of moulded items from homopolymer and modified PTFE determined according to the listed methods.

In brackets the same refers to extruded items.

Thermal properties

Thermal stability

PTFE is one of the most thermally stable plastic materials. It maintains most of its properties up to 260°C. Appreciate decomposition starts over 400°C.

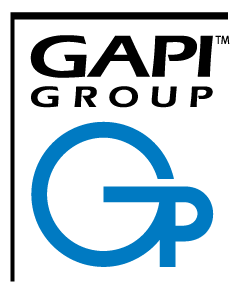

Transition points

The most important points of glass transition in the PTFE are: at 19°C there is an increase in volume and at 340°C PTFE changes from its crystalline structure to an amorphous phase (melting point), while still keeping a high viscosity level.

Expansion

The linear thermal expansion coefficient varies with the temperature. In addition, because of the orientation caused by the working process, the PTFE items are in general anisotropic; in other words, the coefficient of expansion varies also in relation to the direction.

Thermal conductivity

The thermal conductivity of PTFE changes with the temperature variation, however this value remains very low, therefore, PTFE can be considered as a good insulator. The addition of selected fillers will change the thermal conductivity value according to specific applications.

Specific heat

The specific heat can be considered constant if the temperature range is far from the phase transition value.

Fig. 1

PTFE linear thermal expansion and expansion coefficient vs. temperature

Behaviour in presence of chemicals and weathering environments

Resistance to chemicals

PTFE is practically inert to chemicals. It can be attacked only by the alkaline metals in the elementary state, Chlorine trifluoride and Fluorine at high temperatures and pressures.

Solvent resistance

PTFE is insoluble in almost all solvents at temperatures up to about 300°C. Some highly fluorinated oils, at temperatures over 300°C, cause a certain swelling effect upon PTFE.

Resistance to weathering and UV

Specimens of PTFE items, exposed for over forty years to the most variable weather conditions, have not shown any remarkable change of their properties.

Resistance to radiations

PTFE resistance to radiations is limited. It is higher in a vacuum enviroment than in air.

Gas permeability

The permeability does not depend only on the thickness and pressure, but also on the PTFE processing techniques.

Physical - mechanical properties

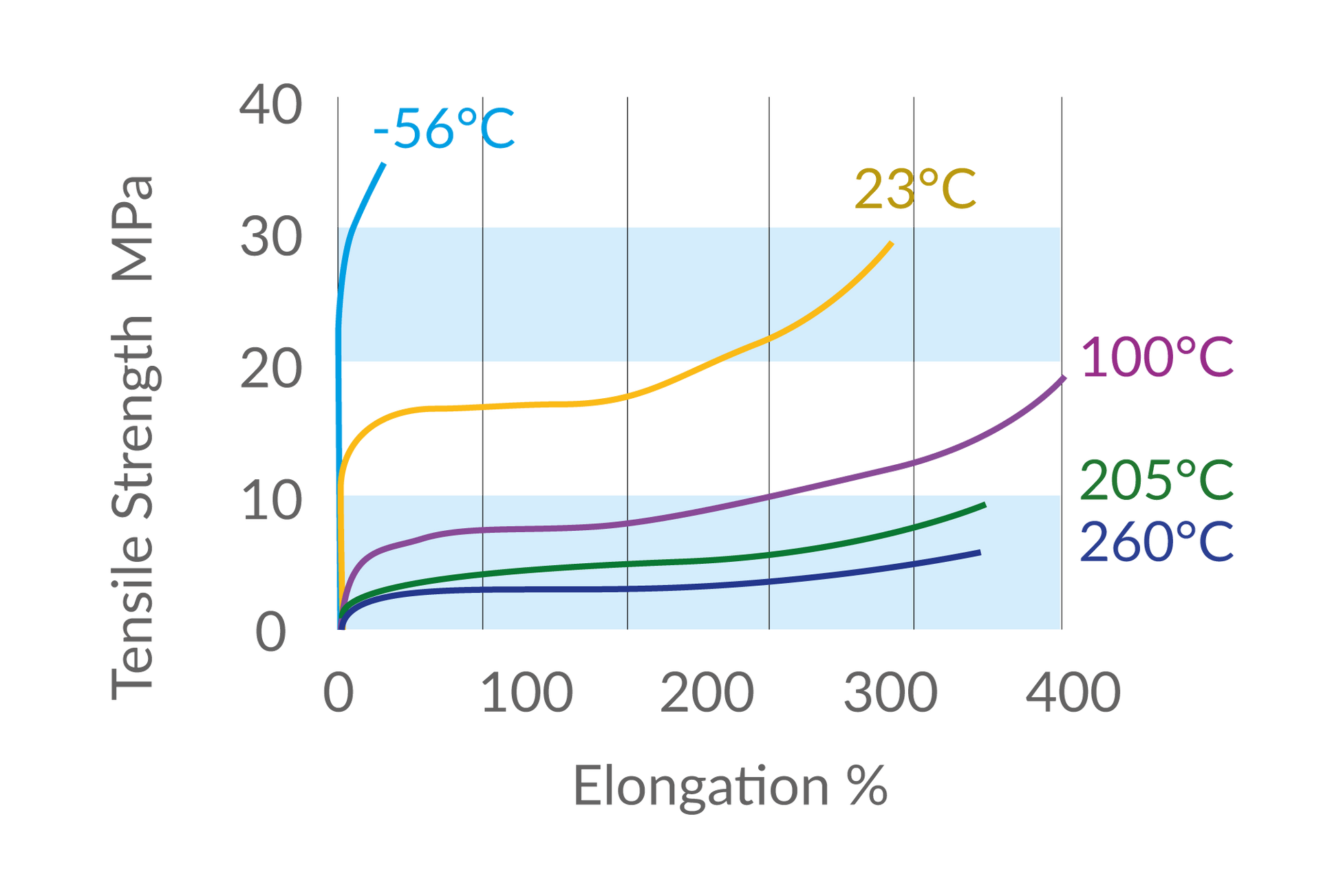

Tensile and compressive properties

These properties are to a large degree influenced by the PTFE processing conditions and the type of polymer. PTFE, however, can be used continuously up to 260°C, while still maintaining a certain plasticity at temperatures near to absolute zero.

The modification of the molecular structure of the polymer (PTFE modified) improves creep properties.

Flexibility

PTFE is quite flexible and does not break when submitted to stresses of 0,7 MPa according to ASTM D 790. Flexural modulus is between 350 to 650 MPa at room temperature, 2000 MPa at -80°C, 200 MPa at 100°C and 45 MPa at 260°C.

Modified PTFE has an improved flex life.

Impact properties

PTFE has very high resilience properties at low temperatures.

Plastic memory

If a piece of PTFE is subjected to tensile or compression stressed below the yield point, it will keep some induced stress (permanent deformation) after the end of the mechanical operation. If the piece is reheated it loses all the induced stress and it returns to its original form. This property is known as "plastic memory" which can be very useful in many applications.

Hardness

The hardness, measured according to the method ASTM D 2240 has values between 50 - 60 Shore D.

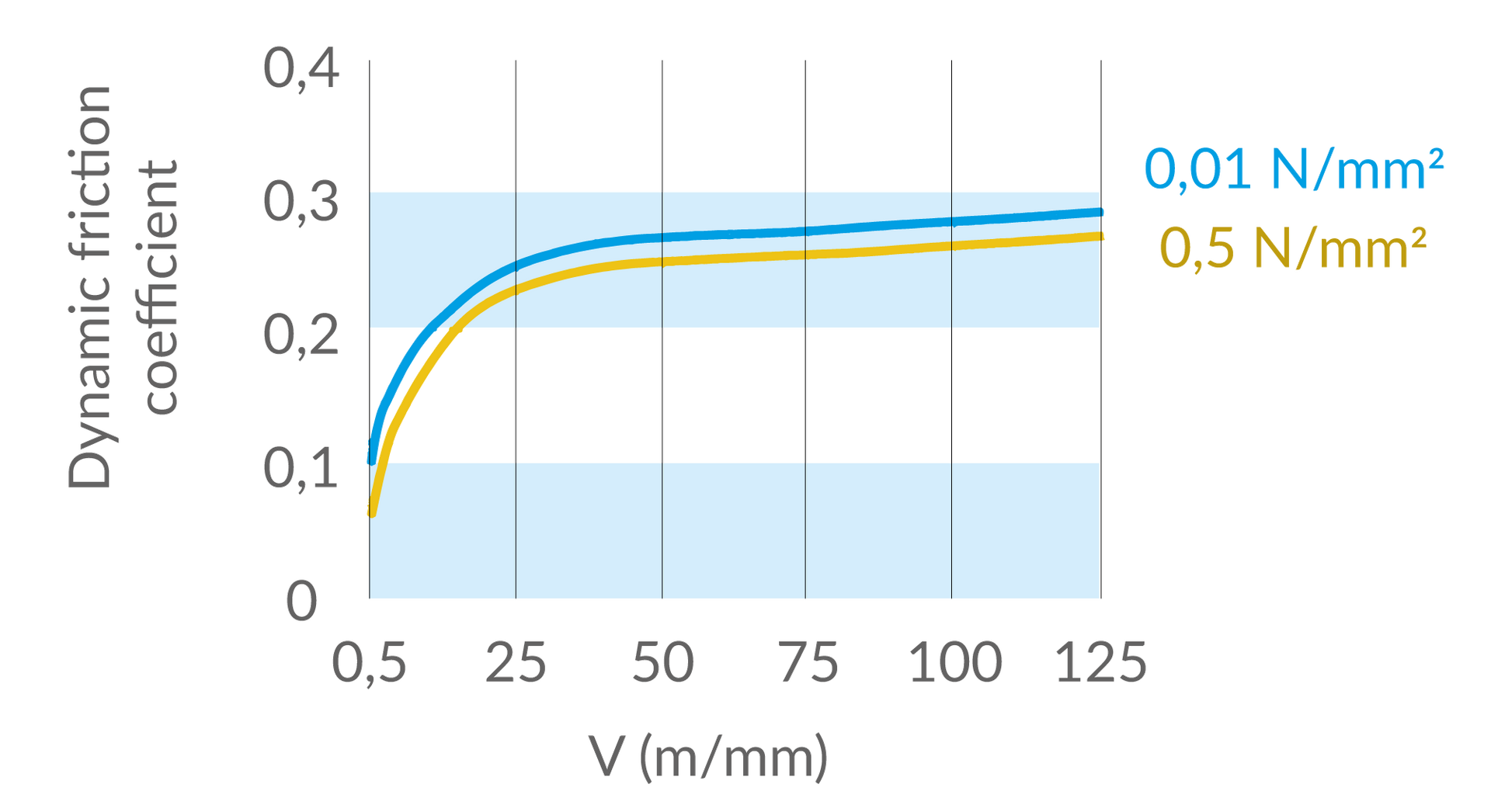

Friction coefficient

PTFE has the lowest friction coefficients of all solid materials, between 0,07(static) and 0,05(dynamic):

the static and dynamic friction coefficients are similar so that there is no seizure or stick-slip action

the friction coefficient increases with the speed (fig.3)

the friction coefficient remains constant with temperature variations.

Wear

The wear depends on the characteristics of the sliding surface, the speed and loads (PV). The wear is considerably reduced when adding suitable fillers to the PTFE (see filled PTFE).

Fig. 2

PTFE tensile strength vs elongation

Fig. 3

Influence of sliding velocity on dynamic friction coefficient

Electrical properties

PTFE is an excellent insulator and as shown by data reported in table 1, maintains these properties throughout a large range of temperatures and frequencies.

Dielectric strength

The dielectric strength of PTFE, depends on the processing conditions, varies with the thickness and decreases with increasing frequency. It remains pratically constant up to 300°C. The modified polymer shows a remarkable improvement in dielectric strength and a lower porosity.

Costante dielettrica e fattore di dissipazione

Il PTFE possiede ottimi valori di costante dielettrica e di fattore di dissipazione; essi rimangono invariati fino a 300°C, in un campo di frequenze fino a 109 Hz e anche dopo prolungato trattamento termico.

Resistenza all’arco

Il PTFE possiede una buona resistenza all’arco. Il tempo di resistenza all’arco secondo ASTM D 495 è di 700 sec..

Anche dopo azione prolungata, non si notano però carbonizzazioni delle superfici.

Resistenza all’effetto corona

Le scariche dell’effetto corona possono anche provocare erosioni alle superfici del PTFE che viene comunemente indicato come isolante idoneo in caso di elevate differenze di potenziale.

Surface properties

The fluor content in molecular configuration of PTFE gives its surfaces high anti-stick properties. For the same reason these surfaces are hardly wettable.

A special etching treatment makes the surfaces bondable and wettable.

Dimensional tolerances

Dimensional tolerances for basic shapes listed in the following tables are for virgin PTFE and refer to standard ISO 13000-1.

Dimensional tolerances shall be measured at 23±2°C.

PTFE - Technical section