PTFE - Technical section

Filled PTFE

granular from suspension polymerization

PTFE, because of the properties previously mentioned, is used in a very large number of applications. Some of its properties can be improved and/or modified by adding suitable fillers, allowing the use of PTFE in applications otherwise precluded to this polymer. The fillers most commonly used are: fibre glass, carbon, bronze and graphite. Other fillers can be: molybdenum disulfide, metal powders, ceramics, metal oxides, polymeric fillers and their blends.

The addition of fillers to PTFE improves or modifies its properties depending upon the nature and the quantity of filler:

- remarkable increase in wear resistance

- decrease of deformation under load/permanent (creep)

- reduction of linear thermal expansion

- coefficient

- increase the thermal and electrical conductivity.

Fillers negatively can influence tensile, resilience and permeability.

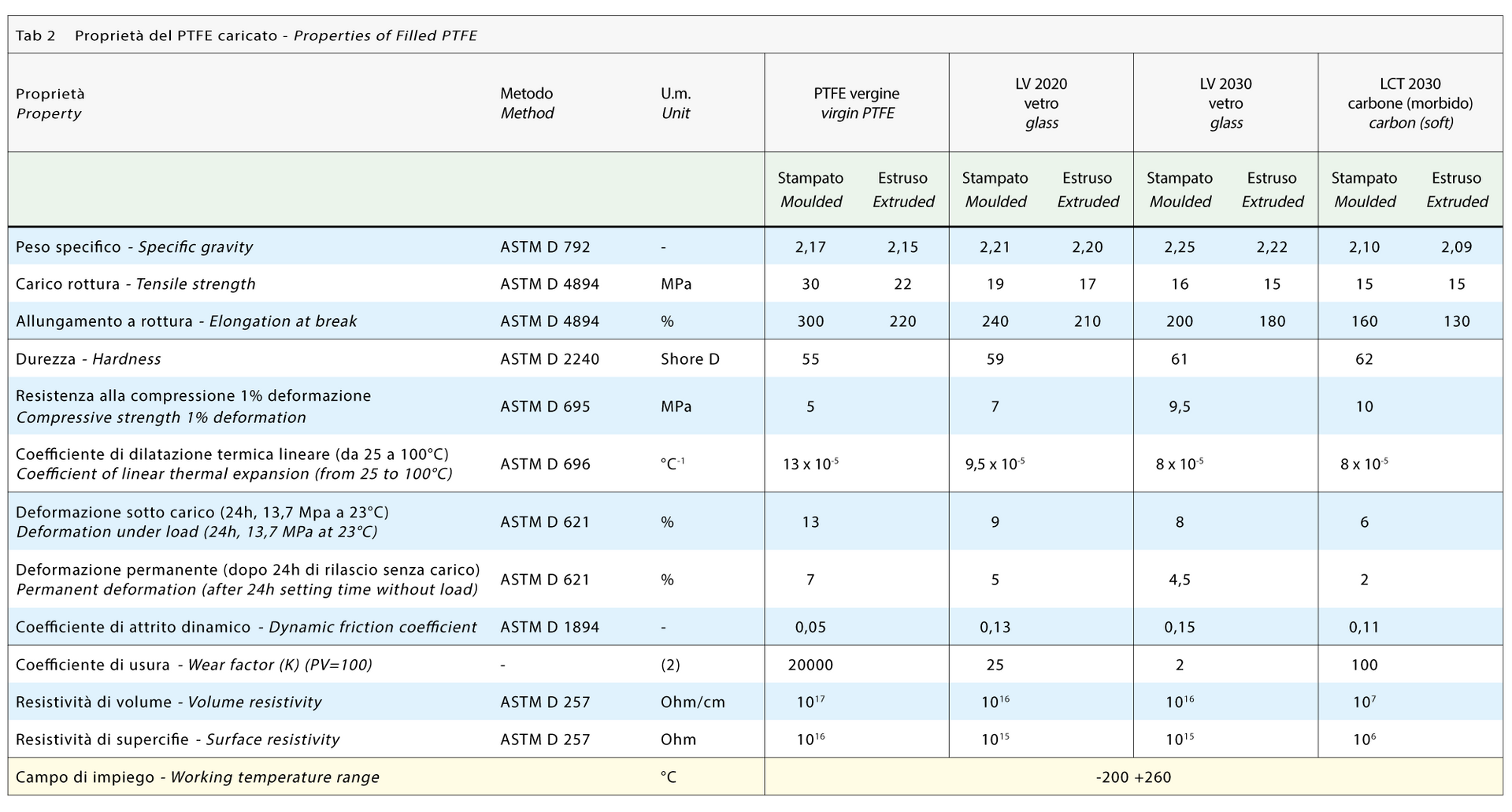

Table 2 shows the main properties of moulded and extruded items.

Fillers functions

Glass fibers

PTFE is reinforced with glass fibres, the percentage may vary between 5 and 40 b.w.. The glass fibre improves the wear properties and also the deformation under load. Glass itself, has a rather poor resistance against alkalis and is easily attacked by hydrofluoric acid. The coefficient of friction is slightly increased and for this reason, graphite or molybdenum disulfide are sometimes added to compensate this negative effect.

Carbon

Carbon is added to the PTFE in a percentage between 10 and 35 b.w., along with a small percentage of graphite. The carbon improves considerably, wear resistance and deformation under load while leaves practically unchanged the chemical resistance. It improves electrical properties.

Bronze

Bronze is added in percentage of 40 and 60 b.w.. Bronze filled PTFE has excellent wear properties, low deformation under load and good thermal and electrical conductivity. The chemical resistance is poor, especially in acidic environment.

Graphite

The percentages used vary between 5 and 15 b.w.. Graphite lowers the coefficient of friction and, therefore is often added to other types of fillers. It improves the deformation under load, and, to a minor degree, the wear properties. It improves thermal and electrical conductivity.

Other fillers

Molybdenum disulfide, decreases the coefficient of friction. Some metal powders (stainless steel), with good chemical resistance are used instead of bronze, even though their wear resistance, is inferior. The metal oxides, in combination with other fillers, give better wear properties.

Physical - mechanical properties

Wear

The contact between two sliding surfaces, because of the friction generated in the contact area, results in a certain wear value, depending on load, speed, time of sliding contact, type and surface finishing. The value of the factor PV over which the coefficient of wear loses its linear correlation, assuming remarkable values with the system passing from weak to strong wear condition, is known as “PV limit”. This PV limit and the wear factor are, therefore, characteristic for each material. In practice, however, it can be easly perceived, the wear factor and the PV limit of the same filled material can vary also with the nature, the hardness and the surface finish of the other contact surface with the presence, or not, of cooling and/or lubricating fluids.

Deformation under load and compressive strength

PTFE, like all plastic materials, has a limited "elastic zone" where the ratio load is, in graphic representation, linear. This ratio is dependent on time, load and final deformation. At the end of the compression the piece will partially return to its shape (elastic recover) that means there is always a permanent deformation. The mechanical properties fall with increased temperatures; at 100°C the recovery is 50% compared to the same test at 23°C.

The value reduces to 10% recovery at 200°C. This applies both filled and unfilled PTFE, with filled PTFE giving better results (table 2).

Thermal properties

The thermal expansion of filled PTFE is in general lower than PTFE and always greater in the direction of the moulding than crosswise. The thermal conductivity is superior to that of unfilled PTFE, particularly when using fillers having a high thermal conductivity. Filled PTFE therefore has better thermal properties (conductivity) than the virgin.

Electrical properties

These properties depend to a large degree upon the nature of the filler. Only PTFE filled with glass fibre, or similar fillers, still maintains acceptable dielectric properties, even though lower than those of unfilled PTFE. Fillers like carbon, graphite and bronze improve anti-static properties and the best results under this respect can be achieved with super conductive carbons.

Dimensional tolerances

Tolerances listed on stock shapes tables refer to virgin PTFE.

For filled PTFE shall be given on request.

Dimensional tolerances shall be measured at 23±2°C.

Tab 2 Properties of filled PTFE

Note:

All the properties have been determinated at 23°C

(1) Speed 0,08 m/sec; load 0,1 N/mm2, sliding surface steel roughness Ra = 0,5 micron

(2) cm3 x min x 10-8/kg x m x h

In the table are reported the most important standard filled grades, On request and depending on the properties needed, Gapi has available a larger range of filled grades with different type and % of fillers both inorganic or polymeric.

Tab 2 Properties of filled PTFE

Note:

All the properties have been determinated at 23°C

(1) Speed 0,08 m/sec; load 0,1 N/mm2, sliding surface steel roughness Ra = 0,5 micron

(2) cm3 x min x 10-8/kg x m x h

In the table are reported the most important standard filled grades, On request and depending on the properties needed, Gapi has available a larger range of filled grades with different type and % of fillers both inorganic or polymeric.

PTFE - Technical section

Terms and use of our Web site, Privacy & Cookie Policy

click and see the Whistleblowing procedure

Copyright 2024 All Rights Reserved

GAPI S.p.A. IT 01440400164